Fly-Presses in the Forge For Forming Metal

What a tongue-twister!

Otherwise known as the ‘Screw’ press, these machines have been around for a long long time. Invented by the Romans in the 1st century AD (thanks Wiki) they rely on a simple screw mechanism that, by weighted wings (fly), bears down on something underneath.

These machines are used in repetitive and labour-intensive jobs in a workshop, for example, the printing press and fruit processing machines, which all work in the same way and for the same desired result; a repetitive process that would require a lot of human energy.

Fly presses have been used to punch holes, cut, shape, and form materials like metal for centuries and by adding weights to the ‘fly’, it means that even less human energy is required in the process.

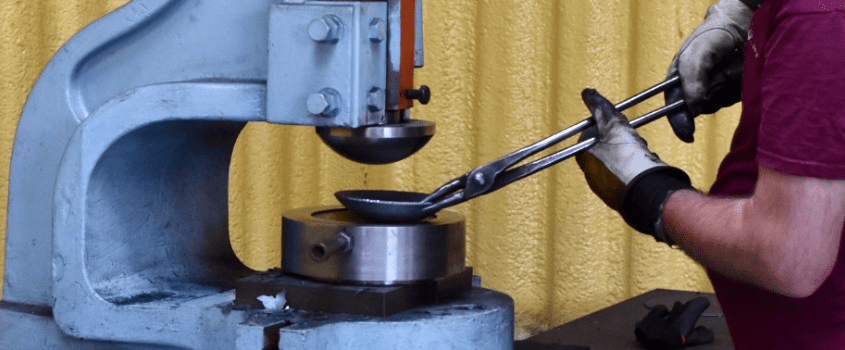

Anything can be added to the Screw (central part of the machine), like a Punch (fitted to the end of the screw) that goes into a Die or a mould underneath. Placing a material, sheet metal, in between these two components, the force of the machine from above can shape the metal unto the Die underneath.

What is a Fly Press doing in the Forge?

We don’t have one, but FIVE presses in our forge! We use them for various processes; to stamp our logo and different designs onto the red-hot metal and we also use the larger ones to form the bowls too! The oldest press is Victorian and the more modern ones were used in the car manufacturing industry. We bought them second-hand and have a variety of sizes and colours for various jobs.

Even though seemingly simple to use a press, it’s actually a very precise and skilled job to – one slip and it could all go wrong in a split second. Not to mention the tendency for metal to blister and produce a lot of ‘scale’ clogging up the process!

Simple machine yet so versatile!

The forge is slowly becoming a fly press museum – we love the fly press! The way in which it can be used is limited only by our imaginations. Chris and Adrian use them most days in the ways described above, but also for new and exciting products.

Along with our plasma cutter, we can cut out a shape and then use a fly press to form it into a different product each time (depending on how we arrange it underneath the punch) and have made some truly unique one-off pieces in our Limited Editions series of products.

Working with screw presses is a very exciting way to work with metal, and we’re sure that we could always find excuses to buy more in the future!

Keep your eyes peeled for some super exciting announcements shortly about the fly-press!